Transformers TRAFOCZ

Trafo CZ, a.s. is a traditional Czech manufacturer of distribution oil transformers TRAFOCZ, which it has been supplying in many designs, power rates and voltages to its customers since 1992.

You should know about TRAFOCZ transformers...

- Trafo CZ, a.s. has been manufacturing and supplying distribution transformers since 1994

- currently, almost 20,000 pieces of TRAFOCZ transformers are installed in networks throughout the Czech Republic

- Trafo CZ, a.s. has been a strategic partner of the ČEZ Group for the supply of distribution transformers since 2010

- Trafo CZ, a.s. is the only manufacturer of transformers with guaranteed service in the territory of the Czech Republic

Supply range of transformers

- voltage rates 6, 10, 22 and 35 kV

- power rates from 50 to 2.500 kVA

- hermetically sealed transformers

- atypical transformers - with low voltage double winding, with low losses, with Midel insulating liquid, with connection to connectors on the HV and LV side

Trafo CZ, a.s. is technologically connected with one of the leading companies in the field - the Hungarian manufacturer Siemens Energy Kft. Trafo CZ uses the development background of the Hungarian partner, which ensures a consistently high standard in the field of technical development, applied production procedures, used materials and quality control system.

Transformer TRAFOCZ - option descriptions

TRAFOCZ hermetically sealed oil-filled transformers are based on the proven TDQ production line, which in small variations is successfully sold all over the world.

Transformer tank

The transformer tank is welded from three basic parts - tub, shell and frame. The massive steel tub is equipped with a discharge fitting and two profile beams that serve as the chassis of the transformer. The shell of the tank is formed by a steel bellows, which enables the cooling and expansion of the used insulating and cooling medium.

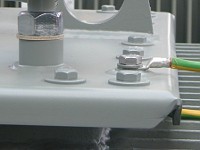

It is thus an important element from the point of view of the transformer's resistance to thermal stress. The frame of the transformer allows the tank and lid to be connected. The tank is equipped with a clamp for connecting the ground and is fitted with a drain cock in the bottom of the tank.

Transformer cover

The cover is made of sheet steel. For higher mechanical strength, all its edges are bent over the upper edge of the tank frame.

The seal between the tank and the lid is provided by oil-resistant rubber with a round cross-section. The lid is connected to the tank by a ground connection.

The cover is made of sheet steel. For higher mechanical strength, all its edges are bent over the upper edge of the tank frame.

The seal between the tank and the lid is provided by oil-resistant rubber with a round cross-section. The lid is connected to the tank by a ground connection.

Transformer coils

The design of the coils varies according to the power and voltage of the machine. Lower powers are wound from round or

profiled wire. For higher powers, copper or aluminum foil is used for the winding on the low voltage side. All coils are of oval cross-section, which leads to smaller dimensions and lower weight of the transformer.

The design of the coils varies according to the power and voltage of the machine. Lower powers are wound from round or

profiled wire. For higher powers, copper or aluminum foil is used for the winding on the low voltage side. All coils are of oval cross-section, which leads to smaller dimensions and lower weight of the transformer.

The sandwich paper insulation is made in Switzerland and ensures high durability of the winding. The coils are wound on modern Stolberg machines in a completely dust-free environment.

Transformer core

The magnetic circuit of the transformer is made of cold-rolled oriented electromagnetic sheets. The sheets are cut on the automated line of the Georg company in the newly built "Core Cutting Center" of the Siemens company in the Budapest production plant.

The core is pulled by steel or wooden beams, and its stiffness and compactness have a significant effect on the losses and noise of the transformer.

Oil in the transformer

The insulating and cooling medium of the TRAFOCZ transformer is Nytro brand transformer oil. It is an inhibited naphthenic oil from the high grade group of high-performance transformer oils by Nynas.

Immediately before filling, the oil is dried and degassed in the Micafil equipment and thus achieves very favorable values of low water content, electrical strength and other parameters monitored for transformer oils. Transformers are filled with oil under vacuum in a vacuum chamber.

Bushings and bolt rings in the transformer

TRAFOCZ transformers are equipped with porcelain bushings as standard. For higher outputs,

nickel-plated eyelets for connecting Cu and Al conductors are also included in the delivery. At the customer's request, the porcelain bushings can be replaced with connectors. The bushings or connectors used come from proven suppliers from EU countries.

TRAFOCZ transformers are equipped with porcelain bushings as standard. For higher outputs,

nickel-plated eyelets for connecting Cu and Al conductors are also included in the delivery. At the customer's request, the porcelain bushings can be replaced with connectors. The bushings or connectors used come from proven suppliers from EU countries.

Transformer surface treatment

The transformer tank, cover and rollers are provided with a double anti-corrosion coating. The standard shade is

RAL 7033, which can be changed according to the customer's request. The tightness of the container is tested twice before shipping for tightness and possible oil leakage.

The transformer tank, cover and rollers are provided with a double anti-corrosion coating. The standard shade is

RAL 7033, which can be changed according to the customer's request. The tightness of the container is tested twice before shipping for tightness and possible oil leakage.

Equipment, devices

All TRAFOCZ transformers are completed with a set of steel rollers. Transformers with an output of 800 kVA and higher are equipped with a two-contact thermometer as standard; on request, the thermometer can be replaced with an integrated R.I.S. or DMCR protection module. The transformer can also be supplemented with a temperature probe PT 100.

Technical specification of offered transformers

TRAFOCZ transformers are offered in several standardized production lines. For specific installations, where there are different requirements for voltage conversion, losses or, for example, oil filling, compared to the standard, the manufacturer offers the option of ordering a transformer completely according to the technical specification.

The advantage of the standard production line is the cost advantage resulting from serial production and also usually faster availability of the transformer in stock.

Technical parameters - ECOD

- the level of losses corresponds to EU Directive 548/2014 - Tier 2

- windings material LV and HV cupper

- design and construction of the transformer is approved for operation in the CEZ Group networks

Transformer technical parameters - ECOD Al

- the level of losses corresponds to EU Directive 548/2014 - Tier 2

- windings material LV i HV aluminium

Atypical transformers

Trafo CZ, a.s. also offers transformers made exactly to order for specific installations. Specific can be transformers for photovoltaic, wind and other small power plants, transformers with double windings on the LV side, with atypical step-up taps of the switch and many other variants. In general, the following parameters can be selected:

- power rate

- voltage on HV, LV side

- number of windings LV

- wiring diagram

- Po losses, Pk losses

- noise level

- oil filing

- number of tappings

- implementation of bushings

- transformer dimension

- equipped with protective devices

- colour, implementation of bolt rings, rollers, marking

Výrobní proces transformátoru

The production of TRAFOCZ transformers is a joint venture between Trafo CZ, a.s. and a foreign partner. The Austrian partner supplies the active parts of the transformer, i.e. coils and cut sheets of the magnetic circuit, which is already being assembled in operation in Hradec Králové. We provide the other parts necessary for the completion of the transformer by our own production or purchase from specialized manufacturers, in many cases foreign.

Transformer manufacturing operations - brief description

- core folding

The core or electromagnetic circuit of the transformer is made of oriented cold-rolled sheets of precisely determined shapes. According to the production regulations, the sheets are folded on a special table from fy Georg using the STEP-LAP method. - installing coils

Coils are placed on the composite E core - the LV and HV windings form one indivisible unit. After precise seating, it is mechanically secured against the core by wedging to prevent vibrations. The magnetic circuit is closed by folding the upper coupling, mounting the tightening beams and attaching the cover. The cover is fitted with HV, LV bushings and a switch. - transformer connection

The following is the connection of the coil terminals from the LV side to the bushings and from the HV side to the switch and then to the bushings. Before drying, the entire transformer is tested with a safe voltage for correct connection. - drying in a vacuum oven

After connection and testing, the transformer is dried in a vacuum oven. This manufacturing step ensures that the combined action of vacuum and elevated temperature evaporates all moisture and the machine is ideally prepared for filling with oil. - filling with oil

After removal from the vacuum drying oven, the transformer is placed in a tank and the entire machine is closed except for the filling tube. The complete machine is placed in a vacuum filling chamber where it is filled with transformer oil under vacuum. This ensures that the oil fills all the air pockets in the transformer and spreads evenly to all the cooling channels and fins. - pressure test and hermetical sealing

After filling, a test is performed on the overall tightness of the transformer against oil leaks by means of a pressure test. After the pressure test, the machine is hermetically sealed. - The transformer must be tested before expedition. In the testing room, they are subjected to all piece tests required by the standard, the result of which is a test report documenting the parameters of the transformer from the factory.

Transformers in stock

Our aim is to have the most requested types of transformers in stock, especially in the 22 and 35 kV version. For exact information please call / write: +420 727 838 803, e-mail: kostalova@trafocz.cz

Transformer maintence instructions

Hermetically sealed TRAFOCZ transformers are essentially maintenance-free machines. Nevertheless, it is necessary to pay at least elementary attention to ensure their trouble-free long-term function.

If you have any questions, please do not hesitate to contact us.

Complete maintenance instructions for the TRAFOCZ transformer

TRAFOCZ operating instructions

Scope of transformer tests

All transformers manufactured by Trafo CZ, a.s. are subjected to a series of unit tests prescribed by ČSN 60076-1 before handing over to the customer.

It is about

- Winding resistance measurement

- Voltage conversion measurement and phase rotation control

- Measurement of short-circuit impedance and short-circuit losses

- Measurement of no-load current and no-load losses

- Piece insulation tests

In the case of a customer's request for a special or type test, the test must be requested at the order stage so that it is included in the total price of the transformer.

Reference list

Trafo CZ, a.s. products fulfills its function in almost 20,000 installations within the Czech Republic. Our customers are mainly energy companies, assembly companies, manufacturers of kiosk transformer stations, industrial enterprises, shopping centers, hospitals or operators of ski and recreation areas.

Provozní návod transformátorů TRAFOCZ

Typ: PDF

Velikost: 879.2 kB

Typ: PDF

Velikost: 468 kB